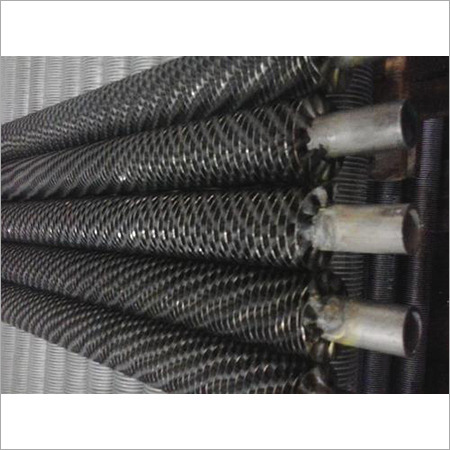

SS Fin Tubes

300.00 INR/Meter

Product Details:

- Material Alluminium

- Shape Round

- Grade Industrial

- Size Different Sizes Available

- Color Black

- Warranty Yes

- Click to view more

X

SS Fin Tubes Price And Quantity

- 300.00 INR/Meter

- 50 Meter

SS Fin Tubes Product Specifications

- Industrial

- Different Sizes Available

- Yes

- Alluminium

- Black

- Round

SS Fin Tubes Trade Information

- 50 Meter Per Week

- 1 Days

Product Description

Stainless steel fin tubes are components used in heat exchangers and boilers to enhance heat transfer efficiency. These tubes have fins (extended surfaces) that increase the surface area available for heat exchange between the fluid inside the tube and the surrounding environment. The fins are typically attached to the outer surface of the tube, creating a larger surface area for heat transfer.

Here are some key points about stainless steel fin tubes:

1. Material:

- Stainless Steel: The use of stainless steel in fin tubes provides corrosion resistance, durability, and heat resistance. Common stainless steel grades used include 304, 316, 321, and 347.

2. Applications:

- Heat Exchangers: Stainless steel fin tubes are commonly used in heat exchangers for various industries, including petrochemical, chemical, power generation, and HVAC (heating, ventilation, and air conditioning).

- Boilers: They are also used in boilers to improve the efficiency of heat transfer.

3. Types of Fins:

- Integral Fins: The fins are formed from the base metal of the tube itself.

- Welded Fins: Fins are attached to the tube by welding. This allows for flexibility in choosing different materials for the tube and fins.

4. Fin Configurations:

- Helical Fins: Spiral fins that run along the length of the tube.

- L/LL/KL Type Fins: These are various types of longitudinal fins with different shapes.

5. Advantages:

- Increased Heat Transfer Efficiency: Fins increase the surface area, improving heat transfer between the fluid inside the tube and the surrounding medium.

- Corrosion Resistance: Stainless steel provides excellent corrosion resistance, crucial in applications where exposure to corrosive environments is a concern.

6. Considerations:

- Cost: Stainless steel fin tubes can be more expensive than alternatives, but their durability and corrosion resistance often justify the cost.

- Design and Manufacturing: The design and manufacturing process of fin tubes is critical to ensuring their effectiveness in specific applications.

7. Maintenance:

- Regular maintenance may be required to ensure the longevity and efficiency of stainless steel fin tubes, especially in applications where they are exposed to harsh conditions.

SS Fin Tubes Specifications:

1. Finishing: Galvanized

2. Size: 3/4 inch

3. Unit Pipe Length: 3 meter, 6 meter

4. Material for Construction: Stainless steel

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Finned Tubes' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |