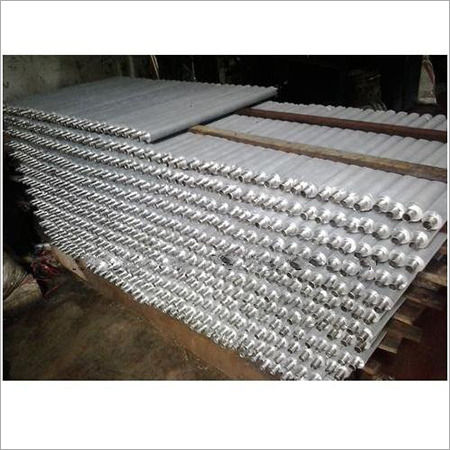

MS Fin Tubes

300 INR/Meter

Product Details:

- Material Alluminium

- Shape Round

- Grade Industrial

- Size Different Sizes Available

- Color Silver

- Warranty Yes

- Click to view more

X

MS Fin Tubes Price And Quantity

- 300 INR/Meter

- 300.00 - 800.00 INR/Meter

- 50 Meter

MS Fin Tubes Product Specifications

- Round

- Silver

- Different Sizes Available

- Industrial

- Alluminium

- Yes

MS Fin Tubes Trade Information

- 50 Meter Per Week

- 1 Days

Product Description

Mild steel fin tubes are components used in heat exchangers and other applications where efficient heat transfer is required. The term "fin tube" typically refers to a tube with extended surfaces, or fins, attached to its outer surface. These fins increase the surface area of the tube, facilitating better heat exchange between the fluid inside the tube and the surrounding environment.

Here are some key points about mild steel fin tubes:

1. Material: Mild steel, also known as carbon steel, is a type of steel that contains a low amount of carbon. It is a popular choice for fin tubes due to its strength, durability, and cost-effectiveness.

2. Construction: The fin tubes are typically manufactured by attaching fins onto the outer surface of a base tube. The fins can be helical or longitudinal, and they significantly enhance the heat transfer capability of the tube.

3. Applications: Mild steel fin tubes find applications in various industries, including HVAC (heating, ventilation, and air conditioning), power generation, chemical processing, and oil and gas. They are commonly used in boilers, air coolers, and heat exchangers.

4. Heat Transfer: The primary purpose of fin tubes is to increase the heat transfer surface area, allowing for more efficient heat exchange between the fluid inside the tube (such as hot water or steam) and the surrounding air or fluid.

5. Corrosion Resistance: While mild steel is durable, it may be susceptible to corrosion in certain environments. Depending on the application, protective coatings or other corrosion-resistant measures may be employed to enhance the longevity of the fin tubes.

6. Customization: The design of mild steel fin tubes can be customized based on the specific requirements of the application, including the geometry and dimensions of the fins.

MS Fin Tubes Specifications:

1. Cross Section: Circular

2. Unit Length: 3m, 6m

3. Type: Integrally Finned Tubes, External Finned Tubes

4. Size: 1 inch-2 inch

5. Material: Stainless Steel

Superior Heat Transfer Efficiency

Our MS Fin Tubes are engineered to maximize heat transfer efficiency in challenging industrial environments. The aluminium construction ensures both strength and optimal thermal conductivity, allowing these tubes to excel in a wide variety of thermal management applications, including oil refineries, power plants, and HVAC systems.

Customizable Sizes for Versatile Applications

To accommodate diverse operational requirements, our fin tubes come in a range of sizes. This flexibility allows seamless integration into existing systems and supports both large-scale and specialized projects demanding precision heat exchange solutions.

Assured Durability and Consistent Performance

With a commitment to quality, we back our MS Fin Tubes with a comprehensive warranty. Manufactured to withstand demanding industrial use, these tubes provide consistent performance, reduced maintenance, and peace of mind throughout their operational life.

FAQs of MS Fin Tubes:

Q: How are MS Fin Tubes manufactured for industrial use?

A: Our MS Fin Tubes are produced using advanced fabrication techniques that bond aluminium fins onto a round base tube, ensuring high mechanical strength and maximized heat transfer efficiency. Rigorous quality controls guarantee suitability for industrial grade demands.Q: What are the primary applications and usage areas for these MS Fin Tubes?

A: These tubes are primarily utilized in heat exchangers across industries like power generation, petrochemical, HVAC, and oil refineries, where efficient heat dissipation and thermal management are critical.Q: When should I consider using MS Fin Tubes in my system?

A: MS Fin Tubes are ideal when you require enhanced heat transfer and reliable performance under harsh operating conditions, or when upgrading or designing industrial thermal systems that demand robust and efficient solutions.Q: Where can your MS Fin Tubes be exported and supplied from India?

A: As a reputed exporter, manufacturer, and supplier, we distribute MS Fin Tubes throughout India and also cater to global clients. We ensure safe, timely delivery to meet your project deadlines.Q: What is the process for selecting the right size and specification for my application?

A: Our technical team assists in evaluating your system requirements, considering parameters like operating temperature, desired heat transfer rate, and spatial constraints to recommend the optimal MS Fin Tube size and configuration.Q: What benefits do aluminium MS Fin Tubes offer compared to other materials?

A: Aluminium MS Fin Tubes provide excellent corrosion resistance, lightweight construction, and superior thermal conductivity, making them efficient and cost-effective choices for long-term industrial use.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Finned Tubes' category

|

THERMAL ENERGY SOLUTIONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |